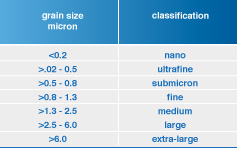

High-performance micro-grain grade, with high hardness and high wear resistance. XS10 is suitable for a wide range of milling, boring, drilling, on metal, wood and stone and molding of synthetic materials.

GRADES - Applications

XF10 is a sub-micron grainsize grade with high hardness and wear resistance. It designed for processing brass without content of lead and stainless steels where a very high level of surface finishing is required. This degree is also suitable for molding of synthetic materials.

XS06 is a ultra-fine grainsize grade suitable for milling and drilling operations with high rotational speed on gray cast iron. Highly performaning even for milling, drilling and cutting of synthetic materials such as CFRP, graphite, hardened steels, as well as titanium alloys and heat resistant alloys.

HC12 is an advanced sub-micron grainsize grade with high cutting performance. This grade is suitable for high-speed machining of steels, titanium alloys and special steels (resistant to heat and corrosion).

XK20 is a medium grainsize grade designed for a wide range of applications on non-ferrous materials, such as brass, aluminum, cast iron copper, as well as plastics. Suitable for heavy machining tools with interrupted cut.

XK30 is a medium grainsize grade designed for a wide range of applications on non-ferrous materials, such as brass, aluminum, cast iron copper, as well as plastics. Suitable for heavy machining tools with interrupted cut.

Medium grainsize grades G are very tenacious and have high resistence to impacts and wear.

All grades G are specific to the rolling, extrusion, deep drawing and stamping processing, either cold or hot, as well as on a wide range of additional applications on non-ferrous metals and their alloys, as well as cast iron.

Medium grainsize grades G are very tenacious and have high resistence to impacts and wear.

All grades G are specific to the rolling, extrusion, deep drawing and stamping processing, either cold or hot, as well as on a wide range of additional applications on non-ferrous metals and their alloys, as well as cast iron.

Medium grainsize grades G are very tenacious and have high resistence to impacts and wear.

All grades G are specific to the rolling, extrusion, deep drawing and stamping processing, either cold or hot, as well as on a wide range of additional applications on non-ferrous metals and their alloys, as well as cast iron.

Medium grainsize grades G are very tenacious and have high resistence to impacts and wear.

All grades G are specific to the rolling, extrusion, deep drawing and stamping processing, either cold or hot, as well as on a wide range of additional applications on non-ferrous metals and their alloys, as well as cast iron.

Medium grainsize grades G are very tenacious and have high resistence to impacts and wear.

All grades G are specific to the rolling, extrusion, deep drawing and stamping processing, either cold or hot, as well as on a wide range of additional applications on non-ferrous metals and their alloys, as well as cast iron.

Medium grainsize grades P are specifically designed for insert and wear-resistant components. The grades P are well suited to the steel-working with machine tools. Their composition makes them highly resistant to the tool side wear. The grades P are also good conductors of heat, therefore they improve the cooling of the tool.

Medium grainsize grades P are specifically designed for insert and wear-resistant components. The grades P are well suited to the steel-working with machine tools. Their composition makes them highly resistant to the tool side wear. The grades P are also good conductors of heat, therefore they improve the cooling of the tool.

GRADES - Technical Data

Our carbide grades, their chemical composition, physical features and recommended applications.

The choice of the most appropriate hard metal quality for the application to be carried out is a very important aspect in the design of an high-performance tool or component.